Manufacturing Capability

When integrity meets passion, it puts success in motion

We have set up the first facility in India capable of the end forging of non-uniform cross section rails used in thick web switches and thick web switch expansion joints.

We have the capacity to forge 14000 rails annually. This is one of the most modern setup comparable to the best in the world.

We have the capacity to forge 14000 rails annually. This is one of the most modern setup comparable to the best in the world.

Forging Plant

We’re proud to have established India’s first facility for end forging non-uniform cross-section rails, which are critical components for Thick Web Switches and Thick Web switch expansion joints. With the capability to forge 18,000 rails annually, this facility is one of the most modern and advanced in the world.

Product Features

- Capable of forging complex, non-uniform rail sections

- Precision-engineered for high durability and performance.

- Engineered to meet modern railway safety and performance standards.

Rolling Mills

We also have a state of the art rolling mill with an annual capacity to roll 100000 MT. We roll cross sections including Fish Plate sections, Liner sections, Sleeper sections, Z bars, bridge expansion joint sections and various unconventional sections according to the specifications and drawings of our clients. We have an expert design team which makes the rolling of these unconventional sections possible.

Product Features

- Capable of rolling a diverse range of specialized sections

- Designed for high-strength and durability

- Customized solutions for unconventional sections

CNC Planers

We have a invested in automated production lines with CNC technology used in various machines , from large CNC planno millers to smaller cutting and punching machines. This automation is what ensures the pinpoint precision and accuracy with which our products are manufactured and what maintains the consistent quality of our products which has led to the formation of the deep rooted trust that our customers have in us.

Product Features

- High-precision machining for complex components

- Automated production for consistent quality

- Versatile operations for a wide range of products

Flaskless Foundry

Our foundry, with an annual capacity of 25,000 MT, focuses on producing large castings like bogies, wagon couplers, and CMS crossings. We operate a fully automated OMEGA fast loop molding line—one of only two in India—allowing us to deliver precise and efficient production.

Product Features

- Automated casting process for high efficiency

- Precise molding for large components

- High-quality finishes with minimal defects

High-Pressure Moulding

We are in the process of setting up a new foundry with an annual capacity of 20,000 MT, dedicated to producing smaller castings such as base plates for turnouts and CP tops and bottoms for bogies. Our investment in a fully automated DISA High-Pressure Moulding line will ensure the highest accuracy in our castings.

Product Features

- Automated high-pressure molding for precision castings

- High throughput with consistent quality

- Capable of producing intricate and smaller components

CMS Welding Facility

Our CMS welding facility is equipped with a rectifier flash butt welding machine with a capacity up to 200 pieces per month.

The latest technology available for leg welding CMS crossings, enabling us to manufacture crossings that meet the most up-to-date and demanding specifications.

Product Features

- Precision leg welding for CMS crossings

- High-capacity welding machine for large-scale projects

- Durable welded crossings that meet stringent railway standards

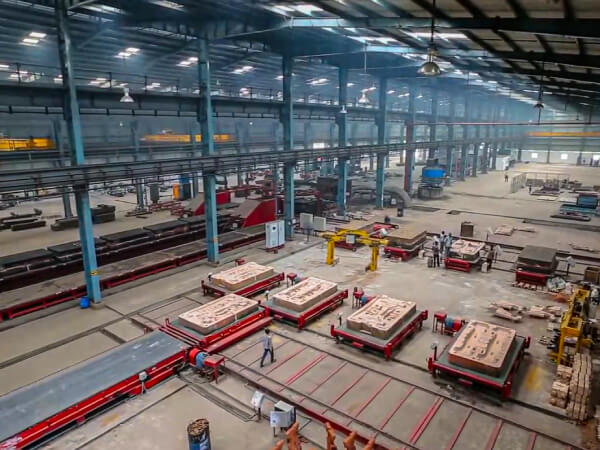

Wagon Plant

Our wagon plant, spanning 250,000 sq ft, is capable of manufacturing 4,800 wagons annually. This facility is fully equipped to produce a variety of wagon types, including Open, Covered, Flat, Hopper, and Tank wagons, catering to diverse industry needs.

Product Features

- Large-scale production for diverse wagon types

- Versatile plant capable of handling various wagon designs

- Meets international standards for strength and durability

Spring Plant

We have an in-house facility for manufacturing springs for bogies, ensuring that we maintain strict control over quality and performance in every spring we produce.

Product Features

- Precision manufacturing for high-performance springs

- Quality-controlled in-house production

- Designed for long-lasting durability and strength

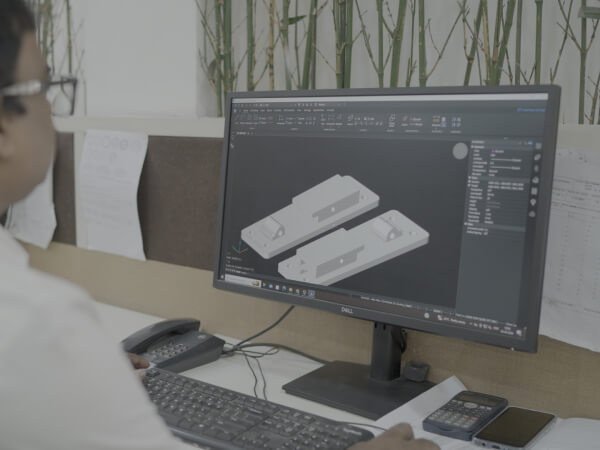

Design & Engineering

With manufacturing facilities in India, Jekay International offers end-to-end solutions to its global customers, based on its extensive technology, product design and product development expertise. The engineering centre processes are well designed to adopt best practices and technology, and to continuously improve upon them to meet the growing challenges.

Product Features

- CNC technology for machining of Thick web switches: The latest technology used for automation.

- Rolling mill technology: We specialize in developing new & complex profiles in our rolling mill at very short notice & delivery time. This is possible through our in-house team consisting of roll pass designers having experience of over 30 years in this field and also through art roll machining facility.

- CAD facilities can show all details by presenting 3D modelling.

Machining

- Our machining facilities comprising of variety of machines like presses, band saws, Plano millers, drills etc. are world-class and comparable to the best in the industry.

Inspection & testing

- We have a world-class Metallurgical, Mechanical and Chemical facilities for Inspection & Testing to ensure higher and consistent level of quality.