About Us

We are the Jekay Group, embarked on a journey of industrial excellence since 1980

Welcome to the world of the Jekay Group, the major industrial partner to the Railway Developers, Government, and Non-Government organizations for 4 decades. The journey of the Jekay group flagged off in 1980 has come a long way loaded with several milestones, achievements, accolades, and today it is one of the leading manufacturers and exporter of Hi-Tech Rail Track Fittings, Turnouts, and Steel Structures ensuring the highest quality full-service railway solutions.

Helmed through the latest technological advancements, the Jekay Group has been developing and delivering solutions that vouch for the best quality and safety, making it a pioneer in its industry with an annual turnover of $100M proudly serving esteemed clientele spanning across the globe.

When quality meets commitment…it signals excellence!

For the JEKAY Group, this founding philosophy has made it a name affiliated with advanced technology, quality and reliability enabling the group to build a long-term, healthy partnership with our valued clients which include the Indian Railways, the Dedicated Freight Corridor project, all the major port authorities, cement plants, steel plants and most of the world leaders in infrastructure development.

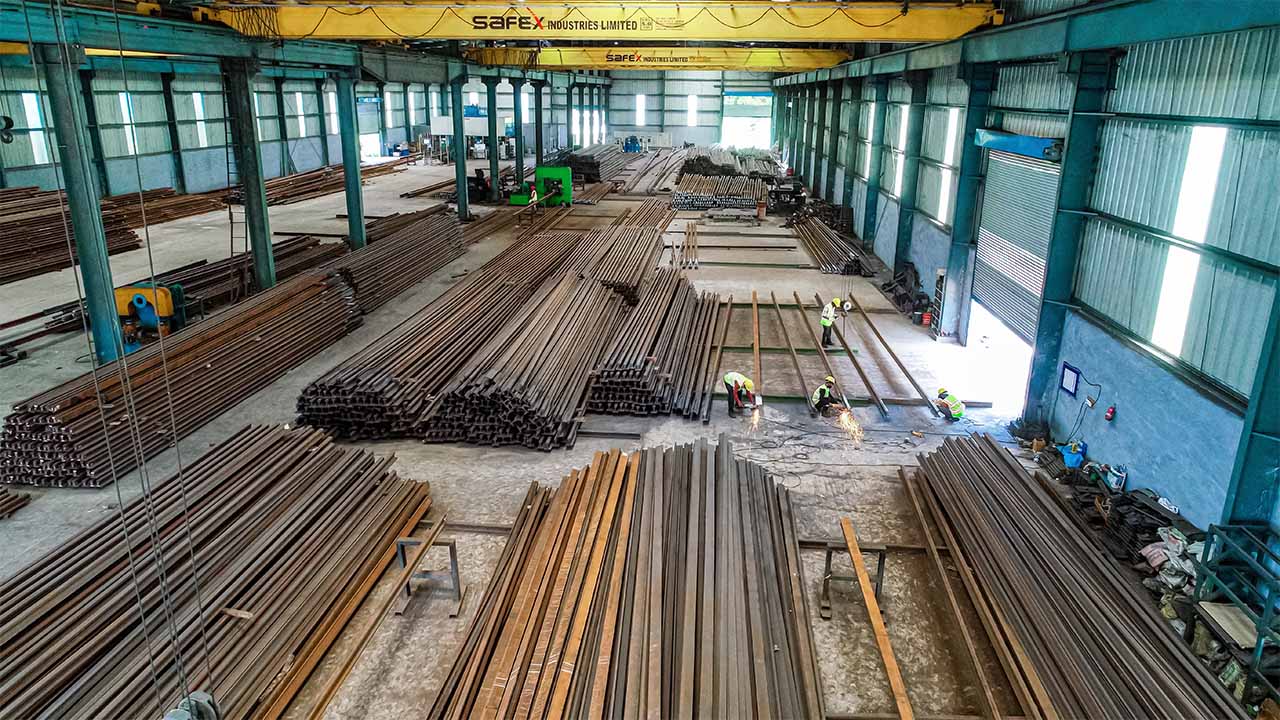

The credit for this goes to our state of the art infrastructure empowered with the latest and avant-garde technology and highly skilled, experienced and motivated employees who handle each process with utmost precision.

Our Mission

Being established as Engineering Manufacturing Company characterized for its excellence in Railway track fittings , structural steel sector & Collector Bar for Aluminium Reduction cell & other steel products relevant to Aluminium Industry.

Our Vision

To achieve up to the entire satisfaction of our clients by supplying product in a healthy environment, conforming to the highest degree in terms of quality, time and safety.

Manufacturing Capability

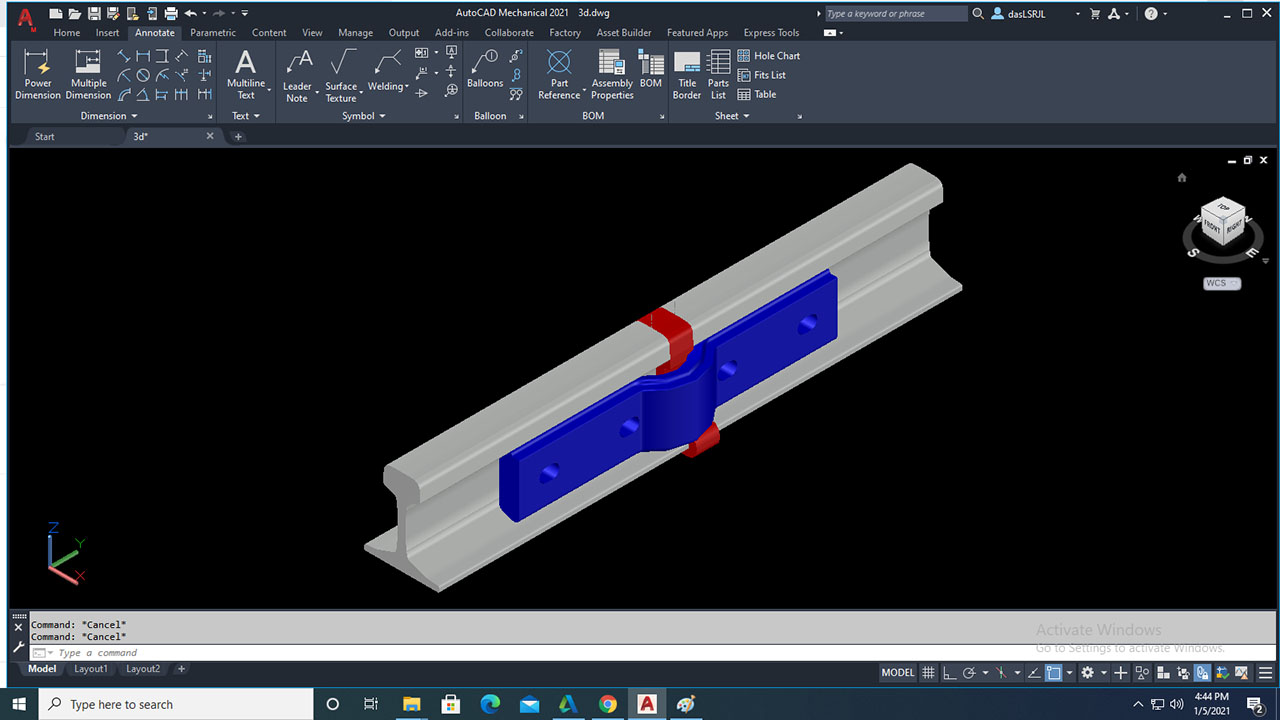

We have set up the first facility in India capable of the end forging of non-uniform cross section rails used in thick web switches and thick web switch expansion joints. We have the capacity to forge 14000 rails annually. This is one of the most modern setup comparable to the best in the world

We also have a state of the art rolling mill with an annual capacity to roll 100000 MT. We roll cross sections including Fish Plate sections, Liner sections, Sleeper sections, Z bars, bridge expansion joint sections and various unconventional sections according to the specifications and drawings of our clients. We have an expert design team which makes the rolling of these unconventional sections possible.

We have a invested in automated production lines with CNC technology used in various machines , from large CNC planno millers to smaller cutting and punching machines. This automation is what ensures the pinpoint precision and accuracy with which our products are manufactured and what maintains the consistent quality of our products which has led to the formation of the deep rooted trust that our customers have in us.

Our Infrastructure

We pride ourselves on delivering the highest quality products available anywhere around the world and thus put special emphasis on our testing facilities which are constantly upgraded with the most advanced of technologies available on the market. Each and every product that leaves our factories goes through extremely stringent testing with tolerances significantly lower than even those accepted by the railways.

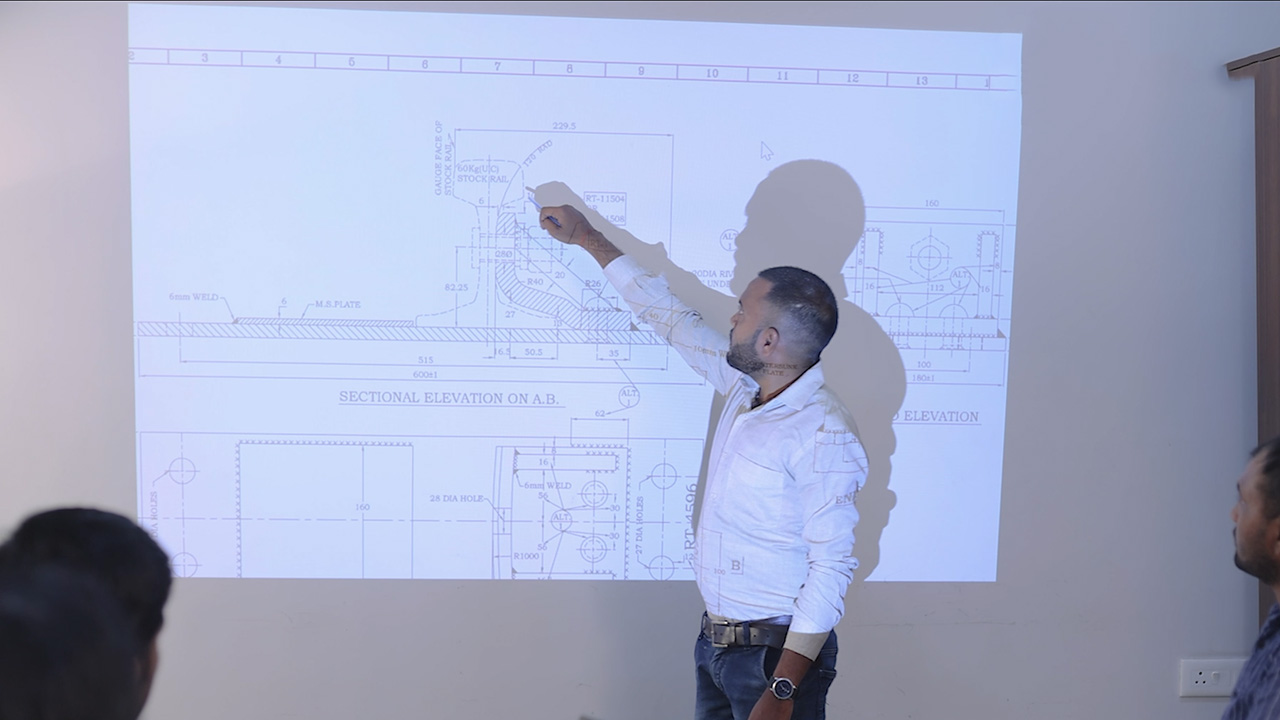

We also take pride in the competency of our design team which has successfully completed various landmark assignments including the design of various crossovers, dual gauge turnouts and canted turnouts to meet the needs of specific customers.

The group has established numbers of manufacturing units with world-class Engineering and designing departments, machining departments and testing facilities.

It is to note that this plant is also equipped to produce 7 million elastic rail clips per annum.

Accreditation

ISO Certification

We have acquired 2008 version of ISO-9001 Certification from Kvalitet Veritas Quality Assurance, Delhi in the name of Jekay International Track Pvt Ltd., Ganpati Industrial Pvt. Ltd. and R.V. Industries Pvt Ltd.

RDSO Certification

We are approved by RDSO, Lucknow in Part-I Category for various types of Fish Plate Bars, Fish Plate, Special Fish Plate, and Metal Liners.

Bureau of Indian Standard (BIS)

We have been granted BIS License by Bureau of Indian Standards,Bhopal in the name of Jekay International Track Pvt Ltd and Ganpati Industrial Pvt. Ltd.

Design & Engineering

The Design & Engineering facility comprises

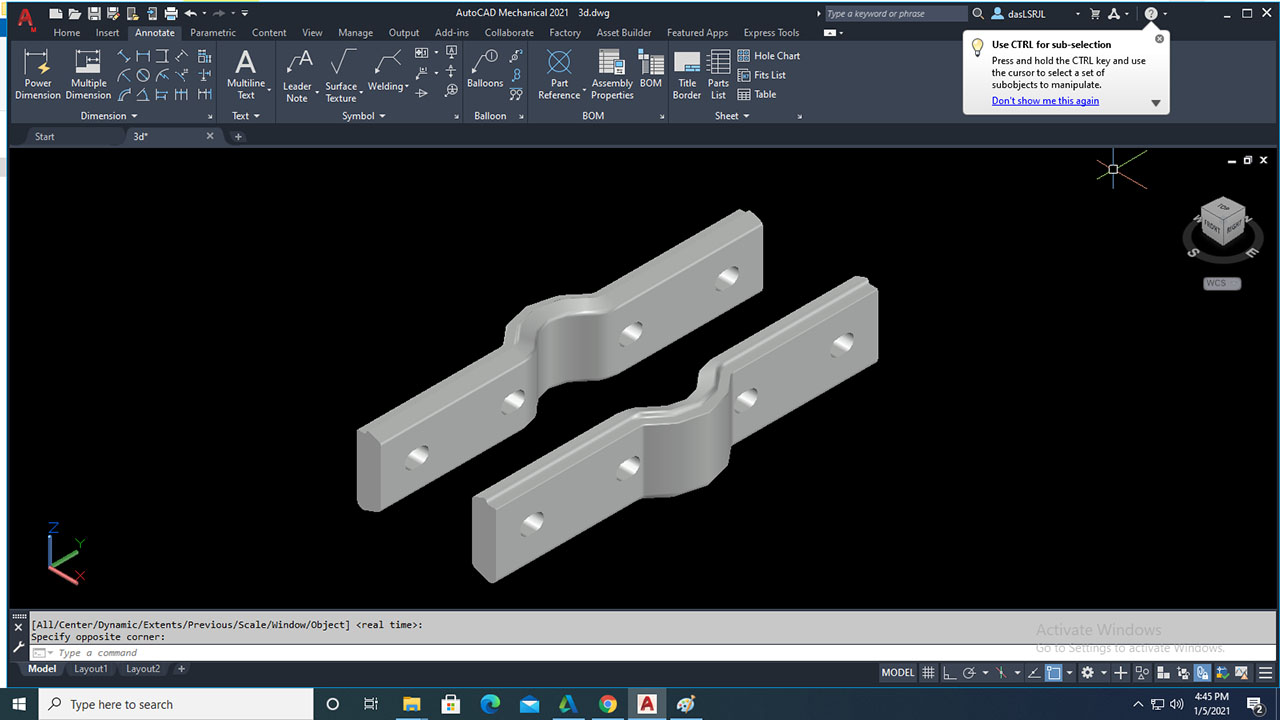

- CNC technology for machining of Thick web switches: The latest technology used for automation.

- Rolling mill technology: We specialize in developing new & complex profiles in our rolling mill at very short notice & delivery time. This is possible through our in-house team consisting of roll pass designers having experience of over 30 years in this field and also through art roll machining facility

- CAD facilities can show all details by presenting 3D modelling

Machining

Our machining facilities comprising of variety of machines like presses, band saws, Plano millers, drills etc. are world-class and comparable to the best in the industry.

Inspection & testing

We have a world-class Metallurgical, Mechanical and Chemical facilities for Inspection & Testing to ensure higher and consistent level of quality.