Turnout System

We manufacture turnouts as per RDSO specification & design as well as our own design. We have design wing, designs complete turnouts with required track gauges BG, SG, MG etc of Indian & international standard with all available rail section.

Thick Web Switch

We offer a complete Thick we switch with Heat Treated Welded Crossing solution ranging from high-speed moveable crossings and their associated actuation, locking and detection systems through to CNC machined mono block tramway switches, which include removable blades.

Switches

The switches are manufactured maintaining the technical specification of IRS, UIC and CEN, as per requirements of the customers. The manufacturing process are employing the latest CAD/CAM systems along with latest manufacturing and testing facilities.

Types of switches we are manufacturing

- Fabricated Curved Switch 1 in 7 , 1 in 8.5 & 1 in 12 for 52 Kg & 60 Kg Rail

- Complete Turnout sets 1 in 7, 1 in 8.5 & 1 in 12 for 60 Kg & 52 Kg Rail with PSC & Steel Sleepers

- Scissor X Over Crossing 1 in 8.5 & 1 in 12 for 52 Kg & 60 Kg Rail & Diamond Crossing

- Derailing Switch for 52 Kg & 60 Kg Rail

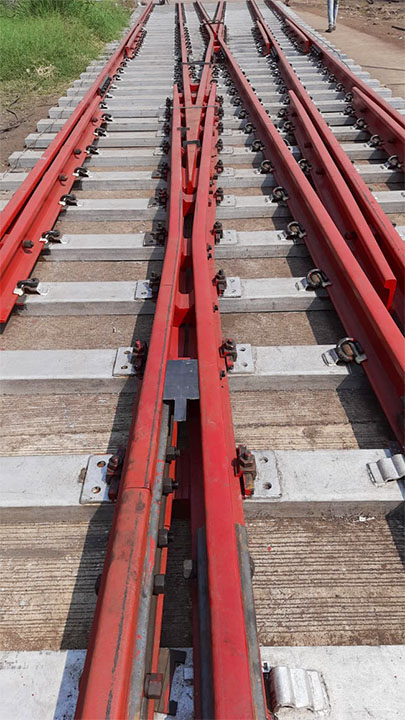

Dual Gauge Turnout

We have successfully designed and manufactured dual gauge turnouts which allow using the same turnout for two different rail gauges (typically meter gauge and standard/ broad gauge) .

Canted Turnouts

We have designed and successfully manufactured Canted Turnouts for Dedicated Freight Corridor Corporation, These are tangential entry turnouts with extremely robust construction for the purpose of higher axle loads at increased speed. We can proudly say that we are one of the only three successful manufacturers of such type of turnouts in the country

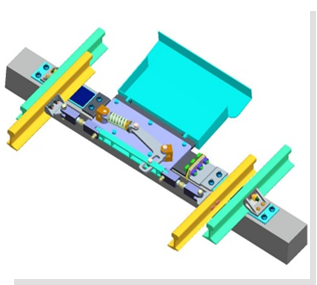

Spring Setting Device (SSD) / Back Drive / Dual drive

The Spring Setting Device ensures the correct setting of the switch rail. It gives exactly the required flange way clearance between the open tongue and stock rails at all times and that too up to the junction of Rail Heads (J.O.H.).

This device functions without any fault, each and every time when the switch is operated. It can be used on all the turnout designs of the railway tracks and has already proven to be perfect in every condition. It is very economical as well as it has a longer life.

Crossings

Swing Nose Crossing

We Manufacture swing nose crossing as per the specific requirements of our customers. These crossings are beneficial to both High Speed and High Axle Load infrastructures, providing impact elimination, noise reduction and very low maintenance.

Swing nose crossings allow for the train wheel to pass through the turnout supported by the rail throughout . By movement of the nose of the crossing as well as the switch of the turnout the turnout track is uninterrupted from entrance to exit. The robust cast manganese cradle gives superior wear and durability performance to the crossing.

Heat treated Welded crossings / Fabricated crossing

Our designed Fabricated Crossings are cost effective and ideal solution for low traffic environments where Manganese Solutions are not required.

We also offer WELDED crossings which can also be heat treated if required. A welded-heat treated crossings has composite welded “V” welded by way of exclusive inhouse electroslag welding process to avoid separate point and splice joints in order to increase the rigidity and the strength of the “V” portion.

This is a unique and robust solution for complex and limited use areas like ‘K” type obtuse crossings, crossovers and dual gauge crossings. These items have high tensile strength and high tolerance level.

We offer these Fabricated V Crossings at most affordable prices to our precious customers. We have a fantastic range of Rail Profile and Sizes to choose from.

Diamond Crossing

Diamond crossing consists of 4 centre-block crossings made from austenitic high-manganese steel (AMS) with fishplate or welded-on closure rails and the corresponding check rails.

We are the manufacturer of complete diamond crossings (with double slip, single slip and without slip) as a single-source supplier of the key components, CMS Crossings and Switches.

Head hardening facility

We introduced an improved rail head hardening technology with adopting new induction heating coil, new coolant and cooling device and new cooling mechanism.

The properties of rail treated by this improved head hardening technique are tested systemically.

We design, manufacture and assemble switches and crossings.

This can be used efficiently for turnout geometries with up to 3 locking levels