Rolling Stock

Open Wagons

Covered Wagons

Flat Type

Hopper Wagons

Well Type

Tank & Special type Wagons

Brake Van

Bogies

Couplers

Open Wagons

Open wagons are a vital component in the transportation of bulk materials such as coal, iron ore, and other mineral ores. Designed for high efficiency, these wagons facilitate the movement of large quantities of raw materials across significant distances. Their robust design and adaptability to different materials make them indispensable in industries such as mining, energy, and metallurgy.

Key features include:

- Carrying Capacity (Payload): Ranges from 58 MT to 80 MT, depending on sub-variants.

- Volumetric Capacity: Ranges from 56 CuM to 69 CuM.

- Material of Construction: Built with either Mild Steel or Stainless Steel, adhering to IRS standards, or a combination of both materials for optimized strength and durability.

Some of the Popular Variants are – BOXNHL (IRS:M44), BOXNS (IRS:M44), BOSTHS (Mild Steel), BOYEL (Mild Steel).

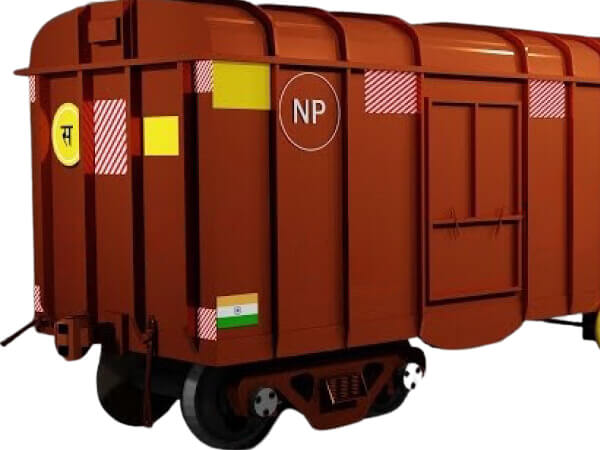

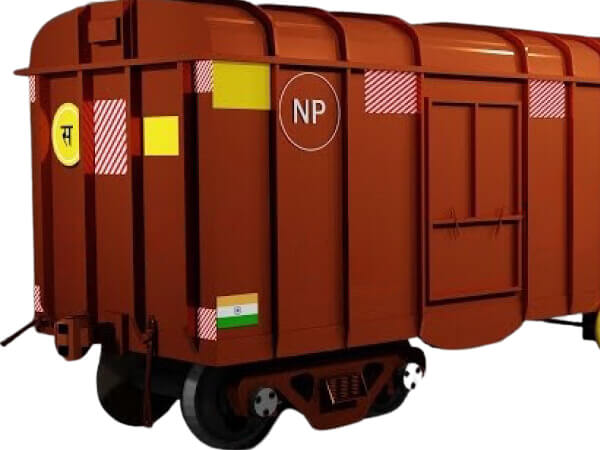

Covered Wagons

Covered wagons play a crucial role in the transportation of bagged or packed goods, including cement, food grains, and other commodities that require protection from the Environment. These wagons are designed to safeguard the cargo during transit, ensuring that goods remain dry and intact throughout the journey. The enclosed structure makes them an essential part of logistics operations in agriculture, construction, and other sectors dealing with bagged products.

Key features include:

- Carrying Capacity (Payload): Ranges from 56 MT to 70 MT, depending on the sub-variant.

- Volumetric Capacity: Ranges from 80 CuM to 104 CuM, providing substantial space for bulk transportation of packed goods.

- Material of Construction: Constructed using Mild Steel or Stainless Steel (IRS:M44) , or a combination of both materials for enhanced strength and longevity.

Some of the Popular Variants are – BCN (Mild Steel), BCNA (Mild Steel), BCNAHS (Mild Steel), BCNHL (Mix of MS And IRS:M44)

Flat Type

Flat type wagons are essential for transporting rolled steel sections, rails, steel coils, and shipping containers.

Key features include:

- Carrying Capacity (Payload): Ranges from 35 MT to 68 MT, depending on the variant.

- Material of Construction: Typically constructed from Mild Steel (IS:2062) or Stainless Steel (IRS:M44) a combination of both Mild Steel and Stainless Steel (IRS:M44), ensuring the durability required for carrying heavy loads.

- Loaded Speed: Varies from 65 Km/h to 100 Km/h, depending on the wagon variant, ensuring timely delivery of goods across vast distances.

Some of the Popular Variants are – BRN, BRNAHS, BRHNEHS Used for transportation of Rails, Steel Rolled sections and coils. BLC, BLA, BLSS are used for transportation of Shipping Containers.

Hopper Wagons

Hopper wagons are specifically designed for transporting bulk materials such as coal, stone ballast, and other mineral ores. These wagons are equipped with bottom and side discharge doors, or a combination of both, allowing for efficient unloading of materials. This makes hopper wagons the ideal choice for industries that require fast, bulk handling of heavy materials, particularly in mining, construction, and energy sectors.

Key features include:

- Carrying Capacity (Payload): Ranges from 55 MT to 70 MT, depending on the variant.

- Volumetric Capacity: Ranges from 34 CuM to 57 CuM, providing ample space for bulk transportation.

- Material of Construction: Made from Mild Steel or a combination of Mild Steel and Stainless Steel (IRS:M44) to ensure durability and resistance to the wear and tear associated with heavy materials.

Some of the Popular Variants are – BOBSN, BOBSNHS, BOBRNHS, BOBYN Etc.

Well Type

Well-type wagons are engineered for the secure and efficient transport of heavy steel coils, serving industries such as steel manufacturing and construction. Their well-shaped design optimizes load stability and distribution, ensuring safe handling and movement of large cylindrical loads over long distances.

Key features include:

- Carrying Capacity (Payload): Up to 56 MT, depending on the sub-variant.

- Material of Construction: Made from Mild Steel, Stainless Steel (IRS:M44), or a combination of both to offer strength, durability, and corrosion resistance for long-term use in industrial applications.

- Loaded Speed: Ranges from 75 Km/h to 100 Km/h, enabling timely and efficient transportation of heavy steel coils.

Some of the Popular Variants are – BFNS, BFNV, BFNSM Etc.

Tank & Special type Wagons

Tank wagons are essential for the bulk transportation of a range of liquids and chemical products, including petroleum, diesel, caustic soda, alumina, and dairy products such as milk. These wagons are engineered with cylindrical tanks designed to securely contain and transport these substances, adhering to stringent safety and efficiency standards. The specialized design and construction of tank wagons make them indispensable in sectors such as petroleum refining, chemical processing, and dairy logistics, ensuring the safe and reliable movement of critical materials across the supply chain.

Key features include:

- Carrying Capacity (Payload):Up to 57 MT, depending on the sub-variant.

- Volumetric Capacity: Ranges from 40 CuM to 70 CuM, offering substantial space for transporting large volumes of liquids.

- Material of Construction: Made from Mild Steel (MS) or a combination of Mild Steel and Stainless Steel (SS), depending on the specific sub-variant, ensuring durability and compatibility with the transported liquids.

- Loaded Speed: Up to 80 Km/h, allowing for timely transportation over long distances.

Some of the Popular Variants are – BTPN (For Petrol/Diesel), BTCS (For Costic soda), BTAP (For Alumina), Milk Vans Etc.

Brake Van

Brake vans, or guard vans, are critical for train operations, offering a designated space for the train guard and incorporating an emergency braking system. Positioned at the train’s rear, they play a key role in maintaining safety, stability, and communication throughout the journey. These vans ensure the train can be safely halted in emergencies and provide the guard with the essential tools to monitor and manage the train’s operations.

Key features include:

- Loaded Speed: These vans can operate at speeds ranging from 75 Km/h to 100 Km/h, ensuring they can match the speed of the train while maintaining safety.

- Material of Construction: Brake vans are constructed from Mild Steel, providing the necessary strength and durability to withstand long-distance train operations.

Some of the Popular Variants are – BVZI, BVCM Etc.

Bogies

3 Piece Cast steel bogies are used majorly in Indian railway Freight rolling stocks.

Casnub-22, Casnub-22 NLB, Casnub 22 HS, LWLH-25, LCCF-20 are the common variants of bogies that are in use in Indian railways freight rolling stocks.

We have an installed capacity to produce up to 600 Bogie sets per month In-house.

Couplers

The High Tensile Knuckle Type (AAR – “E”) Centre Buffer Couplers (CBC) are used in Indian Railways for freight rolling stock. These couplers are designed to provide a secure and efficient connection between freight wagons, ensuring safe and stable transportation of goods.