Introduction: The Unseen Force That Shapes Railway Dynamics

Every time a train sweeps through a curve, a silent negotiation unfolds between physics and engineering. The rails, seemingly rigid, are in fact dynamic participants in this dance, responding to the immense centrifugal forces generated by high-speed locomotives. This unseen force-cant deficiency-shapes the very essence of railway safety, comfort, and efficiency. As one expert put it, “The track is not just a passive guide; it’s an active player in the drama of speed and stability.” For entrepreneurs and railway professionals alike, understanding cant deficiency is not an academic exercise-it’s a prerequisite for mastering the business and science of modern railways.

The Physics of Rail Curvature and Speed: Why Balance Isn’t Always Equal

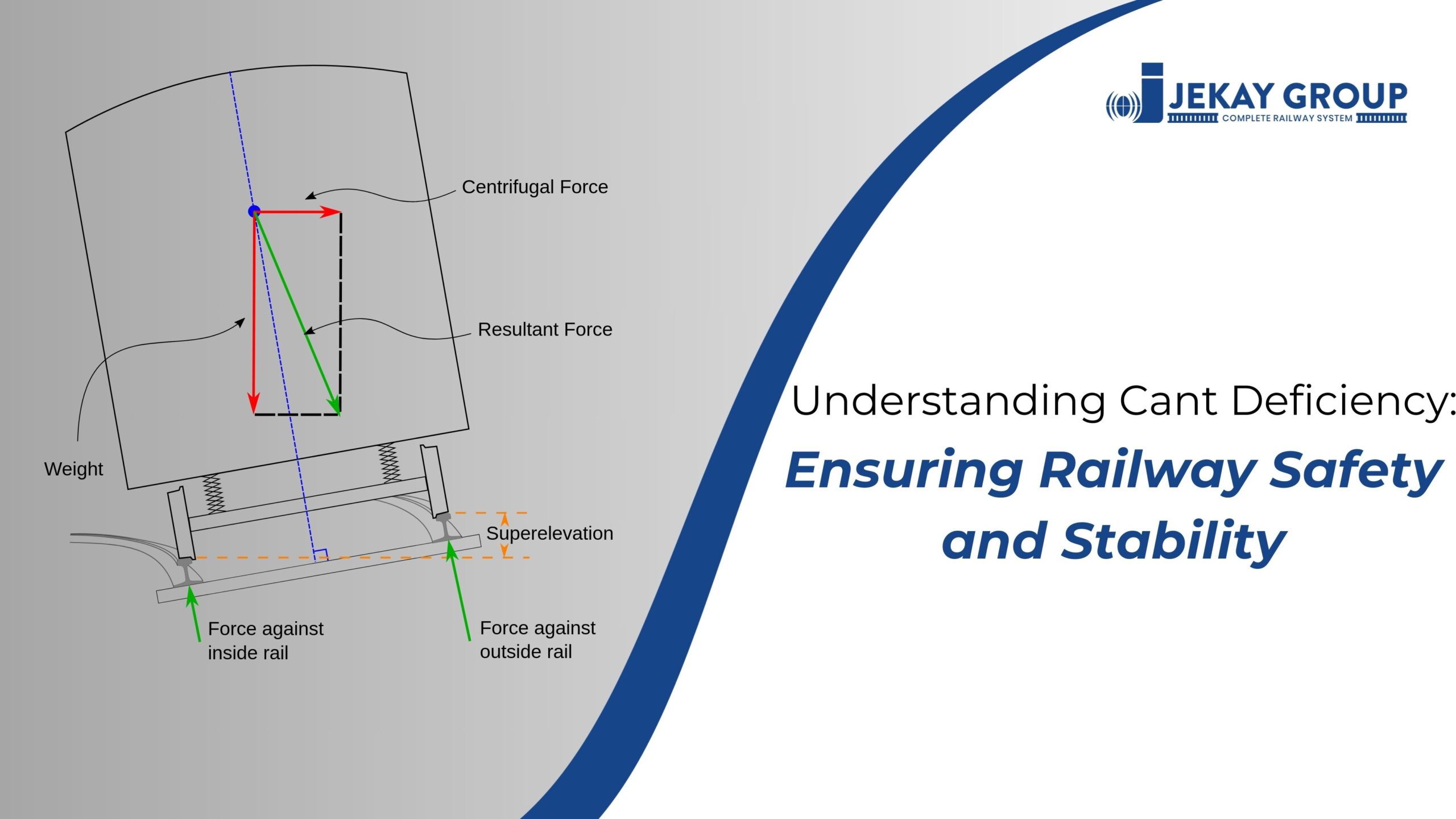

Railways are masterpieces of applied physics. When a train enters a curve, the centrifugal force tries to fling it outward. To counteract this, engineers elevate the outer rail-a practice known as “cant” or superelevation. The ideal scenario is a perfect balance: the train’s speed and the curve’s cant combine so that the resultant force acts perpendicular to the track plane, ensuring both rails share the load equally.

But real-world operations rarely align with this ideal. Passenger and freight trains run at different speeds, and operational constraints often dictate less-than-optimal cant. The result? A persistent imbalance where the outer rail bears more of the load-a condition known as cant deficiency. This isn’t just a theoretical quirk; it’s a fundamental reality that shapes track design, maintenance, and safety protocols worldwide.

What Is Cant and Why Is It Essential in Modern Rail Systems?

Cant, or superelevation, is the difference in height between the outer and inner rails on a curve. It’s the engineer’s tool for “leaning” the train into the curve, much like a cyclist tilting into a turn. The purpose is to balance the outward (centrifugal) force with gravity, minimizing lateral acceleration felt by passengers and reducing wear on the rails.

In practice, the amount of cant provided is a calculated compromise. If the cant matches the equilibrium value for a given speed and curve radius, the resultant force is perfectly vertical. But since trains of varying speeds use the same track, the applied cant is usually set lower than the equilibrium value. This results in cant deficiency-the difference between the equilibrium cant (for the highest speed) and the actual cant provided.

As one British engineering reference explains, “For passenger comfort and to allow for slower trains, the applied cant is always lower than the equilibrium cant. The resulting difference between these two values is called ‘cant deficiency.’” This seemingly small difference has outsized consequences for ride quality, safety, and infrastructure longevity.

Enter Cant Deficiency: The Compromise Between Comfort and Speed

Cant deficiency is the price railways pay for flexibility. It allows a single track to accommodate both fast and slow trains, but it introduces a calculated imbalance. When a train travels through a curve at a speed higher than the equilibrium speed for the provided cant, the resultant force tilts toward the outer rail. This lateral acceleration is what passengers feel as a “push” to the side, and it’s what engineers must carefully manage to avoid discomfort or danger.

The Indian Railways Permanent Way Manual defines cant deficiency as “the difference between the theoretical cant required for such higher speed and actual cant provided.” In India, the maximum permissible cant deficiency for broad gauge tracks is 76 mm, while for meter and narrow gauge, it’s 50 mm and 40 mm, respectively. These limits are not arbitrary-they are the product of decades of research, operational experience, and safety analysis.

Why not simply increase the cant to eliminate deficiency? The answer lies in operational diversity: freight trains, which often run slower, would experience “cant excess” (the opposite problem), leading to their own set of safety and wear issues. Thus, cant deficiency is a deliberate, engineered compromise-a balancing act between competing demands.

Cant Deficiency vs. Cant Excess: Where Engineering Precision Meets Safety Margins

Cant deficiency and cant excess are two sides of the same coin. Cant deficiency occurs when trains run faster than the equilibrium speed for a given cant, while cant excess arises when slower trains encounter more cant than needed. Both conditions shift the balance of forces, but in opposite directions.

Cant deficiency pushes the resultant force toward the outer rail, increasing lateral acceleration and the risk of derailment if limits are exceeded. Cant excess, on the other hand, shifts the load to the inner rail, which can lead to gauge spreading, rail seat deterioration, and increased risk of low rail rollover-especially for heavy freight.

A landmark study by the Federal Railroad Administration summarized the challenge: “The design of curves on shared track requires a compromise between higher-speed passenger and lower-speed freight operations. Significant superelevation helps passenger trains at higher speeds, but it causes deterioration on rail, ties, and surface conditions due to freight operations at substantially lower speeds.” The art of railway engineering lies in finding the sweet spot where neither deficiency nor excess exceeds safe, manageable limits.

Practical Implications: How Cant Deficiency Impacts Track Wear, Passenger Comfort, and Train Performance

Skimmable Insights

-

Track Wear: High cant deficiency increases lateral forces on the outer rail, accelerating rolling contact fatigue and plastic flow. Regular grinding and maintenance are required to manage the “vicious cycle” of rail surface imperfections and escalating wear.

-

Passenger Comfort: Excessive cant deficiency translates to uncomfortable lateral acceleration. Studies indicate that conventional passenger trains could operate at 5–10% higher curve speeds without affecting comfort or safety, but only up to a point. Beyond that, discomfort and risk rise sharply.

-

Train Performance: High-speed trains benefit from cant deficiency, as it allows for faster curve negotiation without excessive cant. However, the trade-off is tighter safety margins and increased reliance on advanced suspension and tilting technologies.

-

Safety Margins: The critical value in track buckling response is the net axle lateral load. Greater track longitudinal forces (from temperature or high cant deficiency) increase the risk of track buckling, especially in hot climates or with heavy axle loads.

-

Regulatory Limits: In the U.S., the FRA limits cant deficiency to 76 mm for conventional vehicles, based on studies dating back to the 1950s. European and Indian standards are similar, reflecting a global consensus on safe operating envelopes.