Every railway journey depends on a contact area smaller than your smartphone screen. This tiny elliptical patch—typically measuring just 14mm by 11mm—must support locomotive weights exceeding 200 tons while transmitting traction forces that accelerate and brake entire trains. Within this microscopic interface, pressures reach 1.2 GPa, equivalent to 12,000 times atmospheric pressure, creating stress concentrations that would instantly crush ordinary materials. The physics governing this extraordinary mechanical interaction determines whether trains operate safely or catastrophically fail, making Hertzian stress analysis fundamental to railway engineering.

The magnitude of forces concentrated within wheel-rail contact patches defies intuitive understanding. A single locomotive axle loading 25 tons creates contact pressures approaching the compressive strength of hardened steel, sustained continuously as wheels roll across thousands of kilometers of track. These extreme conditions exist at every wheel-rail interface throughout railway networks, from high-speed passenger services to heavy freight operations carrying essential commodities. The mathematical models describing these interactions were developed over 130 years ago by Heinrich Hertz, yet remain the cornerstone of modern railway engineering.

Railway systems worldwide process billions of tons of cargo and passengers annually through these minuscule contact patches, each experiencing stress levels that would instantly destroy conventional mechanical components. Understanding why this system works—and when it fails—requires diving into the fundamental physics of elastic contact between curved surfaces under extreme loading conditions.

A Simple Touch, Enormous Pressure: Introducing the Concept of Contact Mechanics

Contact mechanics governs every interaction between solid surfaces, from the grip of your fingers on this screen to the touchdown of aircraft wheels on runways. In railway applications, contact mechanics determines the distribution of enormous forces through minute contact areas, creating stress fields that extend deep into both wheel and rail materials. The wheel-rail contact interaction is crucial to railway operation since it is responsible for supporting, traction, braking, and steering of railway vehicles.

The fundamental challenge of contact analysis involves predicting how curved surfaces deform when pressed together under load. Unlike simple compression, where stress distributes uniformly across flat surfaces, curved contact creates complex three-dimensional stress patterns with maximum values at the contact center. These stress concentrations multiply applied loads by factors of 10-50, transforming moderate wheel loads into extreme material stresses that approach the theoretical strength limits of steel.

Contact mechanics calculations require sophisticated mathematical models that account for material properties, surface geometries, and loading conditions simultaneously. The resulting stress fields exhibit characteristic patterns where maximum values occur slightly below the contact surface, creating subsurface stress concentrations that drive crack initiation and propagation. This phenomenon explains why railway wheels and rails fail through subsurface crack growth rather than surface wear alone.

What Is Hertzian Stress? The Physics Behind Wheel-Rail Interaction?

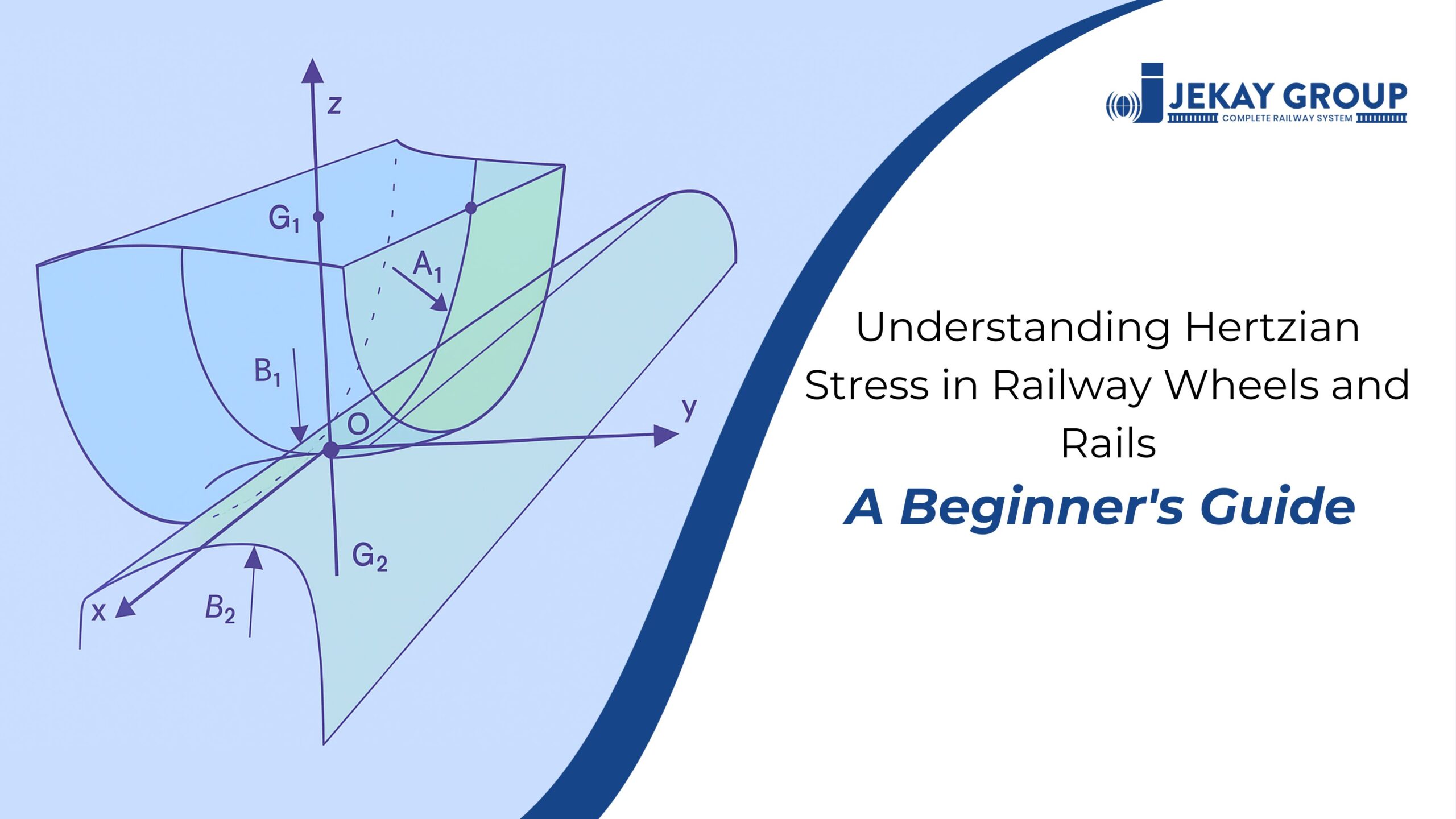

Hertzian stress describes the pressure distribution created when two curved elastic bodies contact under load. Heinrich Hertz developed the mathematical foundation for this analysis in 1882, deriving equations that predict contact patch dimensions and pressure distributions based on material properties and applied forces. The Hertzian contact stress usually refers to the stress close to the area of contact between two spheres of different radii, though railway applications involve more complex geometries requiring advanced mathematical treatment.

The physics underlying Hertzian analysis assumes that contact occurs between smooth, elastic surfaces without adhesion or friction. While real railway wheels and rails violate these assumptions, Hertzian theory provides essential insights into the fundamental mechanics governing wheel-rail interaction. The maximum pressure in a Hertzian contact occurs at the center of the contact patch and decreases to zero at the edges, creating a characteristic elliptical pressure distribution.

For railway applications, Hertzian calculations predict contact patch dimensions typically ranging from 10-20mm in length and 8-15mm in width, depending on wheel radius, rail profile, and axle load. The peak pressure within these patches commonly exceeds 1000 MPa for freight applications and can approach 1500 MPa under extreme conditions. These pressure levels exist continuously as wheels roll across rails, creating cyclic stress patterns that accumulate fatigue damage over millions of loading cycles.

Pressure Points: Where and Why Hertzian Stress Occurs in Rail Systems

Railway wheels and rails develop Hertzian stress wherever curved surfaces contact under load, with maximum stress concentrations occurring at predictable locations throughout the wheel-rail interface. The primary contact point typically occurs at the wheel tread crown contacting the rail head, though secondary contacts develop at the wheel flange-rail gauge corner interface during curve negotiation. Each contact location experiences unique stress patterns determined by local geometry and loading conditions.

Primary Contact Zone Analysis

Wheel Tread-Rail Head Interface

- Contact patch dimensions: 12-16mm longitudinal, 10-14mm lateral

- Peak pressure range: 800-1200 MPa for typical passenger service

- Stress distribution: Elliptical with maximum at the patch center

- Subsurface stress maximum: 0.3-0.5 × contact patch width below surface

Wheel Flange-Rail Gauge Corner

- Contact geometry: Line contact transitioning to point contact

- Peak pressures: 1200-1800 MPa during active steering

- Stress concentration: Extreme localization creating rapid wear

- Failure modes: Gauge corner cracking and flange wear

Secondary Contact Phenomena

Conformal Contact Development

- Wheel-rail profile matching through wear progression

- Increased contact area, reducing peak pressures

- Stress distribution is becoming more uniform

- Long-term contact evolution affecting vehicle dynamics

Two-Point Contact Conditions

- Simultaneous tread and flange contact during curve negotiation

- Complex stress interaction between contact patches

- Load sharing between contact points reduces individual peak stresses

- Dynamic stability implications for vehicle tracking

From Curve to Catastrophe: Real Effects of Excess Stress on Tracks and Wheels

Excessive Hertzian stress creates predictable damage patterns that progress from microscopic material changes to catastrophic component failure. Improper wheel-rail interactions may produce or exacerbate wheel-rail interface issues such as rolling contact fatigue (RCF), requiring a systematic understanding of stress-induced failure mechanisms to prevent operational disasters.

Progressive Damage Mechanisms

Rolling Contact Fatigue (RCF) Rolling contact fatigue represents the primary failure mode for railway wheels and rails subjected to repeated Hertzian stress cycles. Subsurface stress concentrations initiate microscopic cracks that propagate through material grain boundaries, eventually reaching critical dimensions where rapid crack growth occurs. The fatigue process follows predictable patterns where crack initiation occurs at depths of 2-5mm below the contact surface, corresponding to maximum shear stress locations predicted by Hertzian theory.

Plastic Deformation and Flow Hertzian stresses exceeding the material yield strength create permanent deformation within the contact zone. This plastic flow accumulates over repeated loading cycles, altering surface profiles and changing contact geometry. The deformation process redistributes stress patterns, potentially creating new stress concentrations that accelerate subsequent damage progression.

Surface Initiated Cracking. While subsurface fatigue dominates failure mechanisms, surface-initiated cracks develop when Hertzian stresses combine with environmental factors such as moisture, temperature, and contamination. These surface cracks propagate rapidly under continued loading, often leading to sudden component failure without the gradual progression characteristic of subsurface fatigue.

Operational Consequences

Track Geometry Degradation

- Rail head profile changes, altering wheel-rail contact geometry

- Increased dynamic forces from irregular contact patterns

- Accelerated ballast settlement and track geometry loss

- Maintenance requirements are increasing exponentially with stress levels

Wheel Damage Patterns

- Thermal damage from excessive slip during traction/braking

- Flat spot development from wheel slide events

- Tread hollowing from non-uniform wear patterns

- Flange wear requiring premature wheel replacement

Materials Under Microscope: How Composition Affects Stress Resistance

Railway wheel and rail materials must withstand extreme Hertzian stress while maintaining dimensional stability and fatigue resistance throughout extended service lives. Material selection and processing directly influence stress resistance, with composition optimization representing ongoing research frontiers in railway engineering.

Steel Composition Optimization

Carbon Content Effects

- High carbon steels (0.6-0.8% C): Enhanced hardness and wear resistance but reduced ductility

- Medium carbon steels (0.4-0.6% C): Balanced strength and toughness for general applications

- Controlled cooling: Pearlitic microstructures providing optimal fatigue resistance

- Heat treatment: Precise temperature control achieving desired hardness profiles

Alloying Element Contributions

- Chromium additions: Improved hardenability and wear resistance

- Silicon content: Deoxidation and strength enhancement

- Manganese levels: Improved toughness and weldability

- Microalloying: Vanadium and niobium additions for grain refinement

Advanced Material Technologies

Bainitic Rail Steels

- Enhanced fatigue resistance through microstructural control

- Improved wear characteristics under high contact stress

- Reduced internal stress concentrations through refined grain structure

- Extended service life in demanding applications

Head-Hardened Rails

- Selective hardening of rail head surfaces

- Maintained ductility in rail web and base sections

- Optimized hardness profiles for specific contact stress conditions

- Reduced maintenance requirements through enhanced durability

Track Design Meets Contact Science: Role of Rail Profiles, Fasteners, and Transitions

Track design parameters directly influence Hertzian stress distribution through their effects on wheel-rail contact geometry. Safety and economy of railway traffic is enormously influenced by the contact stress variation caused by wheel rail contact profile changes, making design optimization essential for operational safety and economic efficiency.

Rail Profile Engineering

Standard Profile Optimization

- UIC60 rail profiles are designed for balanced contact stress distribution

- Crown radius selection affecting contact patch dimensions

- Gauge corner geometry influencing flange contact stress

- Manufacturing tolerances control contact variability

Asymmetric Profile Design

- Field-side rail head optimization for curve applications

- Reduced gauge corner stress through profile modification

- Improved wheel-rail contact angle for specific traffic types

- Maintenance reduction through enhanced durability

Fastener System Integration

Elastic Fastening Benefits

- Controlled rail deflection under wheel loads

- Stress distribution through extended contact length

- Vibration damping reduces dynamic stress amplification

- Temperature compensation maintains contact geometry

Track Stiffness Optimization

- Vertical track stiffness affecting contact force distribution

- Lateral restraint preventing rail movement under contact forces

- Differential settlement prevention, maintaining contact geometry

- Foundation design supporting consistent track performance

Transition Zone Management

Geometry Transition Design

- Gradual profile changes minimize stress concentration

- Cant transition rates controlling lateral stress development

- Vertical alignment maintains consistent contact conditions

- Construction tolerances ensure smooth stress transitions

How Jekay Components Help Distribute and Minimize Stress?

Advanced fastening systems play crucial roles in managing Hertzian stress through their influence on track stiffness, geometry maintenance, and dynamic response characteristics. Jekay’s engineering approach focuses on optimizing these parameters to minimize peak contact stresses while maintaining long-term geometric stability.

Controlled Compliance Systems

- Engineered elasticity distributes wheel loads across extended rail lengths

- Optimized vertical stiffness, reducing peak contact pressures

- Lateral restraint maintains proper wheel-rail contact geometry

- Dynamic damping characteristics minimize stress amplification

Geometric Stability Enhancement

- Precision manufacturing maintains a consistent track geometry

- Thermal expansion accommodation prevents stress concentrations

- Long-term dimensional stability reduces maintenance requirements

- Installation tolerances ensure optimal contact conditions

Load Distribution Optimization

- Multi-point load transfer reduces localized stress concentrations

- Integrated design approach considering ethe ntire track system response

- Material selection optimizing strength-to-weight ratios

- Fatigue resistance ensures extended service life under cyclic loading

Fatigue, Cracking, and Failure: Common Damage Patterns and Early Warning Signs

Hertzian stress-induced failures follow predictable patterns that enable early detection through systematic monitoring programs. Understanding these failure mechanisms allows the implementation of proactive maintenance strategies, preventing catastrophic component failure.

Characteristic Failure Modes

Subsurface Crack Initiation

- Crack nucleation at maximum shear stress locations (2-4mm depth)

- Initial crack sizes: 0.1-0.5mm, requiring specialized detection methods

- Propagation rates: 0.01-0.1mm per million loading cycles

- Critical crack lengths: 10-20mm before rapid propagation

Surface Damage Patterns

- Head checking: Longitudinal surface cracks from repeated stress cycles

- Shelling: Subsurface crack propagation to the surface, creating material loss

- Spalling: Localized material removal from stress concentration points

- Corrugation: Periodic surface waviness from dynamic contact forces

Early Warning Detection Methods

Visual Inspection Indicators

- Surface crack patterns indicating subsurface damage progression

- Wear pattern changes suggesting altered contact conditions

- Material discoloration from thermal stress during heavy braking

- Geometric irregularities affecting wheel-rail contact quality

Advanced Monitoring Technologies

- Ultrasonic testing detects subsurface crack development

- Eddy current inspection identifies surface crack networks

- Thermal imaging reveals stress concentration hot spots

- Dynamic measurement systems monitor contact force variations

Easy And Practical Methods to Measure and Manage Hertzian Stress

Effective Hertzian stress management requires practical measurement techniques and systematic monitoring protocols accessible to railway operators with varying technical capabilities. Modern measurement approaches combine traditional engineering analysis with advanced sensing technologies to provide actionable stress assessment data.

Contact Stress Calculation Methods

Hertzian Formula Application

- Input parameters: wheel radius, rail radius, axle load, material properties

- Contact patch dimensions: Length = 2a, Width = 2b from established equations

- Peak pressure calculation: P₀ = 1.5 × Load / (π × a × b)

- Stress distribution: Elliptical pressure pattern with maximum at center

Finite Element Analysis

- Advanced modeling accounting for complex geometries and material properties

- Non-linear analysis including plastic deformation effects

- Dynamic analysis incorporating speed and acceleration effects

- Parametric studies optimizing design variables for stress reduction

Field Measurement Techniques

Instrumented Wheelsets

- Strain gauge arrays measuring wheel-rail contact forces

- Telemetry systems transmitting real-time stress data

- Statistical analysis identifying peak stress events and trends

- Correlation with track geometry and vehicle operating conditions

Track-Based Measurement Systems

- Instrumented rails with embedded strain sensors

- Wayside monitoring stations recording contact force variations

- Integration with train identification systems for load correlation

- Long-term data collection supporting maintenance planning

Stress Management Strategies

Operational Control Methods

- Speed restrictions in high-stress track sections

- Load limits for specific vehicle types and track conditions

- Seasonal adjustments accounting for thermal stress effects

- Traffic routing optimization, distributing wear patterns

Maintenance Optimization

- Rail grinding programs maintain optimal contact profiles

- Wheel truing schedules prevent irregular contact patterns

- Track geometry maintenance, ensuring consistent contact conditions

- Component replacement scheduling based on stress accumulation models

Futureproofing the Ride: Smarter Materials, Smarter Design

The future of railway engineering lies in intelligent systems that adapt to changing contact conditions while maintaining optimal stress distribution. Emerging technologies promise revolutionary improvements in material performance, monitoring capabilities, and predictive maintenance strategies.

Next-Generation Materials

Smart Steel Alloys

- Self-healing materials incorporating shape memory effects

- Gradient hardness profiles optimized for specific stress distributions

- Nano-structured surfaces providing enhanced fatigue resistance

- Composite materials combining strength with damping characteristics

Surface Treatment Innovations

- Laser processing creates controlled surface textures

- Ion implantation enhances subsurface material properties

- Coating technologies providing wear resistance without brittleness

- Thermal treatments optimizing residual stress patterns

Intelligent Monitoring Systems

Real-Time Stress Assessment

- Continuous monitoring of contact stress variations

- Predictive analytics identifies developing failure conditions

- Automated adjustment of operational parameters based on stress data

- Integration with maintenance scheduling systems

Machine Learning Applications

- Pattern recognition identifies abnormal stress patterns

- Predictive modeling, forecasting component of life expectancy

- Optimization algorithms balancing stress distribution across networks

- Autonomous maintenance systems responding to stress threshold exceedances

The convergence of advanced materials science, sensor technology, and artificial intelligence promises railway systems that actively manage Hertzian stress while maximizing operational efficiency. These developments will transform railway engineering from reactive maintenance to predictive optimization, ensuring safer and more reliable transportation for generations to come.

Understanding Hertzian stress represents more than an academic exercise—it provides the foundation for safer, more efficient railway systems. The physics governing wheel-rail contact determines whether trains operate reliably or fail catastrophically, making stress analysis essential knowledge for anyone involved in railway engineering, operations, or management.