Beneath the Surface: Why Hidden Defects Threaten Rail Integrity?

Railway disasters don’t announce themselves with dramatic structural failures. They begin as microscopic cracks propagating through seemingly solid steel, invisible to the naked eye yet catastrophic in their potential. A single hairline fracture in a rail clip—measuring mere micrometers in width—can escalate into complete fastener failure, derailing trains carrying hundreds of passengers at operational speeds. The insidious nature of material defects in railway components demands detection methods capable of revealing what traditional inspection cannot see.

Hidden defects in rail fastening systems represent a particularly dangerous category of infrastructure vulnerability. Unlike obvious wear patterns or visible corrosion, subsurface discontinuities develop within the crystalline structure of ferromagnetic materials through cyclic loading, thermal stress, and manufacturing irregularities. These internal flaws remain completely invisible during visual inspection, yet create stress concentration points that accelerate crack propagation under operational loads. When a rail clip experiences millions of load cycles from passing trains, microscopic voids become critical failure points that compromise entire fastening systems.

The economic stakes surrounding undetected defects extend far beyond component replacement costs. Railway networks processing thousands of tons of cargo daily operate on razor-thin safety margins where component reliability directly impacts operational capacity. A single fastener failure can cascade into track geometry problems, speed restrictions, and service disruptions, costing millions in lost productivity. The detection sensitivity requirements for railway components therefore exceed those of many other industrial applications, demanding inspection methods capable of identifying defects measuring less than 0.1mm in critical dimensions.

Magnetic Particle Inspection (MPI): The Nondestructive Test Railways Rely On

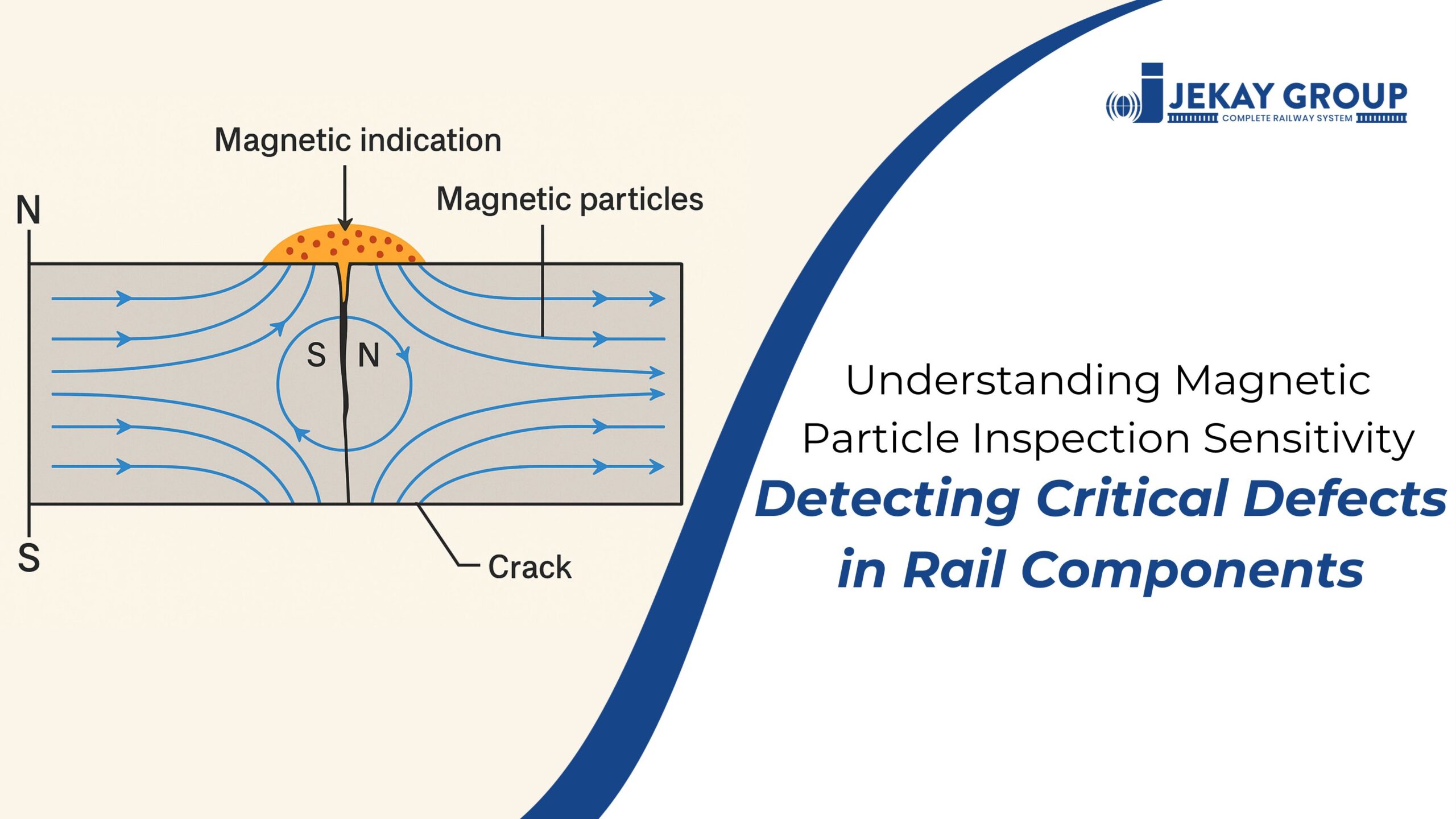

Magnetic particle inspection represents the cornerstone of railway component quality assurance, providing unmatched sensitivity for detecting surface and near-surface defects in ferromagnetic materials. This electromagnetic phenomenon exploits the fundamental physics of magnetic field disruption to reveal discontinuities invisible to other inspection methods. When magnetic flux encounters a crack or void within magnetized steel, it creates a localized field disturbance that attracts specially formulated magnetic particles, creating visible indications of otherwise hidden defects.

The technique’s reliability stems from its direct relationship with material physics. Ferromagnetic materials like steel naturally conduct magnetic flux along predictable paths determined by their crystalline structure. Discontinuities—whether cracks, inclusions, or voids—create barriers that force magnetic flux to leak from the component surface. These flux leakage fields possess sufficient strength to attract and retain magnetic particles applied during inspection, creating accumulations that trained technicians can evaluate against established acceptance criteria. The method can detect surface or near-surface flaws such as cracks, laps, seams, and inclusions in ferromagnetic materials such as iron and steel. One of the main advantages of magnetic particle inspection is that it can give an immediate indication of defects and discontinuities.

Modern MPI applications in railway component manufacturing employ both wet and dry particle systems optimized for specific defect types and operating conditions. Wet particle inspections utilize finely divided magnetic particles suspended in petroleum distillates or water-based carriers, providing enhanced sensitivity for detecting tight cracks and small discontinuities. Dry particle methods employ magnetic powders applied directly to component surfaces, offering superior portability for field inspections and maintenance applications. Fluorescent magnetic particle inspection represents the most sensitive variant, utilizing particles that fluoresce under ultraviolet illumination to reveal defects measuring less than 25 micrometers in width.

Sensitivity Defined: What Makes MPI Capable of Spotting Critical Flaws

The sensitivity of magnetic particle inspection depends fundamentally on the technique’s ability to detect magnetic flux leakage fields generated by material discontinuities. This detection capability operates on multiple physical principles that interact to determine the minimum defect size detectable under specific inspection conditions. Understanding these principles enables optimization of inspection parameters to achieve maximum sensitivity for critical railway components.

Magnetic flux density represents the primary factor governing MPI sensitivity. Higher flux densities create stronger leakage fields at discontinuity locations, improving the ability to attract and retain magnetic particles. However, excessive magnetization can mask small defects by creating broad magnetic fields that obscure localized flux leakage patterns. Optimal magnetization levels for railway components typically range between 2000-4000 gauss, sufficient to generate detectable flux leakage while maintaining definition for small crack indications.

Particle characteristics directly influence sensitivity through their magnetic responsiveness and physical properties. Magnetic particle inspection is particularly effective for identifying and evaluating surface and slightly subsurface defects in ferromagnetic materials during inspections, including crack formations, seams, laps, and voids. High-quality magnetic particles exhibit high magnetic permeability, enabling rapid response to weak flux leakage fields. Particle size distribution affects sensitivity through mobility and retention characteristics—particles too large cannot enter tight cracks, while particles too small lack sufficient magnetic moment to respond to weak leakage fields. Optimal particle formulations balance these competing requirements through controlled manufacturing processes that produce consistent size distributions and magnetic properties.

The geometric relationship between defect orientation and applied magnetic field determines detection probability. Linear defects oriented perpendicular to magnetic field lines create maximum flux disruption and generate the strongest leakage fields. Conversely, defects parallel to field lines produce minimal flux disturbance and may remain undetected. This orientation dependency necessitates multi-directional magnetization techniques for comprehensive inspection coverage, particularly critical for railway components experiencing complex stress patterns during service.

Key Variables That Influence Detection Accuracy in MPI

Detection accuracy in magnetic particle inspection results from the complex interaction of multiple variables that must be optimized simultaneously to achieve reliable defect detection. These variables operate within narrow tolerance ranges where small deviations can significantly impact inspection effectiveness, making systematic control essential for consistent results.

Magnetization Parameters

Field Strength Optimization

- Insufficient magnetization: Creates weak flux leakage insufficient for particle attraction

- Excessive magnetization: Generates broad magnetic fields masking small defects

- Optimal range: 2000-4000 gauss for typical railway steel components

- Verification methods: Hall effect gaussmeters and magnetic field indicators

Current Selection Criteria

- AC magnetization: Concentrated surface fields maximizing surface crack detection

- DC magnetization: Deeper penetration revealing subsurface discontinuities

- Half-wave DC: Balanced surface and subsurface sensitivity for complex geometries

- Multi-directional techniques: Sequential perpendicular magnetization ensuring complete coverage

Environmental Control Factors

Temperature Influence

- Curie point effects: Magnetic permeability reduction at elevated temperatures

- Thermal expansion: Geometric changes affecting magnetic field distribution

- Particle viscosity: Temperature-dependent flow characteristics impacting mobility

- Optimal range: 60-100°F for consistent particle performance

Surface Preparation Requirements

- Cleanliness standards: Oil, grease, and contamination preventing particle adhesion

- Surface roughness: Texture effects on particle retention and indication visibility

- Coating thickness: Non-magnetic layers reducing flux leakage detection

- Chemical compatibility: Particle-surface interactions affecting indication formation

Material, Geometry, and Magnetism: The Interplay Behind Inspection Limits

The fundamental physics governing magnetic particle inspection creates inherent limitations that define the technique’s detection capabilities. Understanding these physical constraints enables realistic expectations for defect detection while identifying opportunities for sensitivity enhancement through parameter optimization.

Material Property Dependencies

Railway components manufactured from different steel grades exhibit varying magnetic characteristics that directly impact MPI sensitivity:

- High-carbon steels: Enhanced magnetic permeability improving flux conduction and leakage field strength

- Alloy compositions: Chromium and nickel content reducing magnetic permeability and detection sensitivity

- Heat treatment effects: Microstructural changes altering magnetic domain structure and flux patterns

- Work hardening: Stress-induced magnetic property changes affecting field distribution uniformity

Geometric Constraints

Component geometry creates fundamental limitations on magnetic field distribution and defect detection capabilities:

- Edge effects: Field concentration at component boundaries creating false indications

- Section thickness: Magnetic field penetration depth limiting subsurface defect detection

- Complex shapes: Irregular geometries producing non-uniform magnetization and coverage gaps

- Sharp corners: Stress concentration points requiring enhanced inspection attention

Magnetization Limitations

The physics of magnetic field generation imposes constraints on achievable sensitivity levels:

- Skin effect: AC magnetization penetration limited to surface layers (0.1-0.5mm depth)

- Demagnetization factors: Component geometry affecting internal field strength distribution

- Magnetic hysteresis: Residual magnetism interfering with subsequent inspection cycles

- Field uniformity: Magnetizing equipment limitations create variable sensitivity across component surfaces

Real-World Relevance: Defect Types Common in Rail Clips, Base Plates, and Fasteners

Railway fastening components experience unique loading conditions that generate characteristic defect patterns requiring specialized detection approaches. Understanding these failure modes enables optimization of MPI parameters for maximum detection effectiveness in critical applications.

Rail Clip Defect Patterns

Stress Concentration Failures Rail clips experience millions of load cycles from passing trains, creating predictable failure patterns:

- Fatigue cracks: Initiating at high-stress regions including bend radii and contact points

- Crack progression: Following material grain boundaries and stress field directions

- Critical locations: Toe and heel regions where maximum bending stresses occur

- Size thresholds: Cracks exceeding 1mm length approaching critical propagation rates

Manufacturing Discontinuities

Production processes introduce defects that compromise long-term performance:

- Forging laps: Surface folds created during hot forming operations

- Inclusion chains: Non-metallic particles aligned during rolling processes

- Heat treatment cracks: Thermal stress fractures from rapid cooling cycles

- Surface decarburization: Carbon depletion reducing fatigue resistance

Base Plate Vulnerability Points

Load Transfer Defects: Base plates distribute wheel loads across larger areas, creating specific failure modes:

- Bearing surface cracks: High-contact stress generating subsurface crack initiation

- Bolt hole cracking: Stress concentration around fastener penetrations

- Corner failures: Geometric discontinuities creating multi-axial stress conditions

- Corrosion-induced cracking: Environmental degradation accelerates crack propagation

Fastener System Integration Issues

Systemic Failure Patterns: Individual component defects can cascade into system-wide failures:

- Preload loss: Gradual fastener loosening increases dynamic stresses

- Geometric mismatch: Component tolerance accumulation creating stress concentration

- Material incompatibility: Galvanic corrosion between dissimilar metals

- Installation damage: Field handling creates surface discontinuities and stress risers

About 7000 rail clips are required per kilometer of railway line, which is directly related to rail safety, making defect detection sensitivity crucial for operational safety.

Jekay’s Commitment to Quality: Elevating Standards Through Advanced MPI Protocols

Quality excellence in railway component manufacturing demands inspection protocols that exceed industry minimum standards. Jekay’s approach to magnetic particle inspection integrates advanced techniques, rigorous process controls, and continuous improvement methodologies to achieve unparalleled defect detection sensitivity.

Enhanced Sensitivity Protocols

- Multi-frequency magnetization: Combined AC/DC techniques maximizing surface and subsurface coverage

- Fluorescent particle systems: UV-illuminated inspection achieving 25-micrometer crack detection

- Automated particle application: Consistent coverage, eliminating human variability

- Statistical process control: Continuous monitorin,g ensuring inspection parameter stability

Advanced Equipment Integration

- Digital magnetization systems: Programmable current waveforms optimized for specific component geometries

- Environmental control chambers: Temperature and humidity regulatio,n maintaining consistent particle performance

- Automated handling systems: Reducing contamination and geometric positioning errors

- Real-time monitoring: Continuous verification of magnetization levels and particle effectiveness

Quality Assurance Innovation

- Reference standard validation: Daily verification using calibrated artificial defects

- Technician certification: Comprehensive training programs exceeding Level II NDT requirements

- Process documentation: Complete traceability from raw material through final inspection

- Customer feedback integration: Field performance data driving continuous process improvement

From Lab to Line: Integrating MPI into Scalable Manufacturing Workflows

Successful implementation of advanced MPI protocols requires seamless integration with high-volume manufacturing operations while maintaining inspection sensitivity and throughput requirements. This integration challenges conventional approaches by demanding automated systems capable of handling complex geometries at production speeds.

Automated System Architecture

Component Handling Integration

- Robotic positioning: Precise component orientation ensuring optimal magnetization angles

- Multi-station processing: Parallel inspection lanes maximizing throughput capacity

- Quality routing: Automatic segregation of components based on inspection results

- Data integration: Real-time quality information feeding manufacturing execution systems

Process Parameter Control

- Adaptive magnetization: Automatic adjustment based on component geometry and material properties

- Particle management: Automated mixing, application, and recovery systems

- Environmental monitoring: Continuous temperature, humidity, and lighting control

- Calibration automation: Scheduled reference standard verification, maintaining sensitivity standards

Production Scalability Solutions

High-Volume Processing Modern railway component manufacturing requires inspection systems capable of processing thousands of components daily:

- Throughput optimization: Multi-directional magnetization in single-pass operations

- Batch processing: Simultaneous inspection of multiple similar components

- Inventory management: Automated tracking and segregation based on inspection results

- Maintenance scheduling: Predictive maintenance minimizes unplanned downtime

Quality Data Analytics

- Trend analysis: Statistical monitoring identifying process drift before quality impact

- Defect correlation: Linking inspection results with field performance data

- Process optimization: Continuous improvement through data-driven parameter adjustment

- Supplier feedback: Quality metrics driving raw material specification enhancement

Setting the Benchmark: Toward More Sensitive, Standardized, and Safer Rail Systems

The evolution of magnetic particle inspection technology continues advancing detection sensitivity while addressing the increasing demands of modern railway operations. These technological developments promise enhanced safety margins through improved defect detection capabilities and standardized inspection protocols.

Emerging Technology Integration

Digital Enhancement Systems

- Image processing: Computer vision systems identifying particle accumulations with sub-pixel accuracy

- Artificial intelligence: Machine learning algorithms recognizing defect patterns exceeding human capabilities

- Augmented reality: Inspector assistance systems highlighting potential defect locations

- Remote monitoring: Centralized quality oversight across multiple manufacturing locations

Advanced Particle Development

- Nano-particle formulations: Enhanced sensitivity through improved magnetic responsiveness

- Smart particles: Color-changing indicators providing immediate defect severity assessment

- Biodegradable carriers: Environmental compatibility without sensitivity compromise

- Multi-modal detection: Combined magnetic and fluorescent properties optimizing visibility

Industry Standardization Initiatives

Global Harmonization

- ISO integration: International standards development ensuring consistent quality expectations

- Performance benchmarking: Quantitative sensitivity standards replacing subjective assessment

- Certification requirements: Enhanced technician qualifications supporting advanced inspection methods

- Documentation protocols: Standardized reporting formats enabling performance comparison

Safety Margin Enhancement

- Reduced acceptance limits: Lower allowable defect sizes reflecting increased detection capabilities

- Mandatory inspection frequencies: Risk-based scheduling optimizing safety and cost effectiveness

- Traceability requirements: Component history tracking enabling proactive maintenance strategies

- Performance validation: Field testing confirming laboratory inspection effectiveness

Final Thought: Every Micron Matters When Millions Ride on It

The microscopic world of material defects operates by unforgiving physics where hairline cracks measure their impact in human lives rather than engineering units. Magnetic particle inspection stands as the critical barrier between hidden material discontinuities and catastrophic failure, transforming invisible threats into detectable indications that trained professionals can evaluate and act upon. The sensitivity achieved through advanced MPI protocols represents far more than manufacturing quality control—it embodies the engineering principle that safety margins exist to protect human life, not accommodate cost reduction.

Railway infrastructure serves millions of passengers and billions of dollars in cargo annually, operating within safety margins that depend fundamentally on the integrity of individual components weighing mere pounds. The failure of a single rail clip can initiate a cascade of events leading to derailment, making every microscopic defect a potential disaster requiring detection before it reaches critical dimensions. This responsibility transforms MPI from a routine quality procedure into a critical safety system where detection sensitivity directly correlates with public welfare.

The investment in advanced magnetic particle inspection technology and protocols generates returns measured not merely in reduced warranty claims or maintenance costs, but in prevented accidents, protected lives, and maintained public confidence in railway transportation safety. When millions of people trust their safety to railway systems, every micron of defect detection sensitivity represents a commitment to engineering excellence that transcends traditional manufacturing quality metrics.

Magnetic particle inspection sensitivity represents the invisible foundation upon which railway safety depends. The commitment to advanced detection protocols, rigorous process controls, and continuous technological advancement ensures that hidden defects remain hidden no longer, revealed through electromagnetic precision before they can threaten the millions who depend on railway transportation for their daily lives and economic prosperity.